Customer Service Hotline:

400-831-9091

E-mail:gzhengde@163.com Tel:13924139149

ADD:Foshan rich Ann industrial zone rich even road no. 25

↵

TEL:400-831-9091

Copyright ©2018 Guangzhou Hengde Construction Technology Co., Ltd. All right reserved ICP:18070461-1

GUANGZHOU HENGDE

PRODUCT CENTER

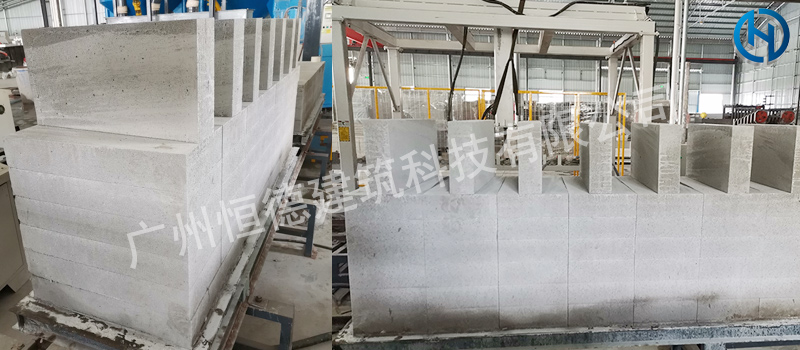

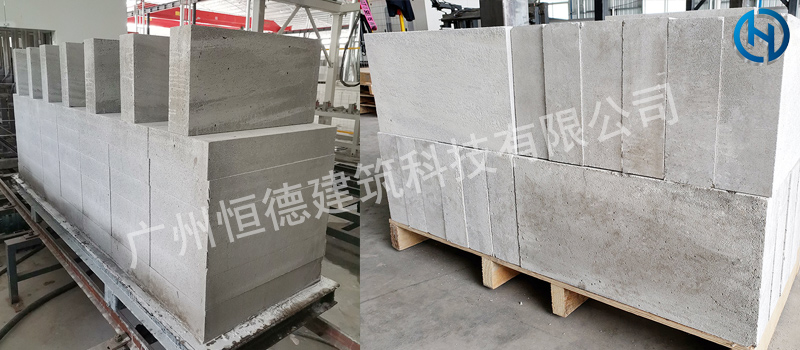

This large-scale integrated-lightweight foam brick equipment (free steam-pressing maintenance) adopts the advanced technology of German CLC block, which can produce new wall materials such as foam brick, lightweight brick, steam-free aerated block and aerated brick. Policy support and promotion, the market prospects are broad. The product has high strength, light weight and no cracking.

First, the characteristics of lightweight foam brick equipment

1. Provide a series of supporting services such as complete sets of equipment and technical formulas, planning and setting up factories and installation training.

2. the real "automatic production line", mechanized operation, labor intensity is small, women workers can also operate.

3. Exclusive European and American patent formula, the product has high strength, no cracking and no water absorption, and the strength is above 4.0mpa.

4. using the "special pre-condensation kiln" foaming patent technology, can be quickly demoulded, can be written into the contract. (The company has another: 8 to 10 minutes of rapid release of technical formula and equipment)

5. the mold is automatically recycled, only 4-6 workers, saving mold and plant, saving 20-30 million additional investment than semi-self equipment.

6. using the patent "360 degree rotary cutting saw" flat cutting and symmetrical vertical cutting equipment, can be dry cut, wet cut, no dust without damage.

7. Equipped with an exclusive “autothermal cycle finished product maintenance kiln”, which can be produced all year round, and the product strength is more stable.

8. Equipment price: According to the degree of automation and configuration, the price is different, and the customer has flexible choice.

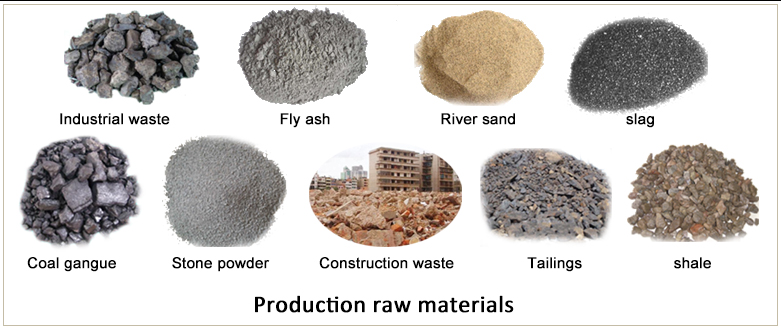

9. the choice of raw materials, low cost: such as fly ash, river sand, slag, slag, tailings sand, stone powder, etc. can be produced (choose one of them)。

10. Good product strength: Under certain humidity and temperature, the quality of lightweight bricks and block bricks through natural curing is more stable than autoclaved blocks. Although the autoclaved block has a fast increase in strength through steaming for a short period of time, the long-term (28d) is not as good as the natural curing strength.

Advantages of cutting saw: high-precision, high-strength block brick cutting, fast speed, neat appearance, standard size, no shortage of corners and other angles.

Second, the equipment required for the plant, water and electricity and raw materials

The production line adopts automatic batching and electronic metering, with high degree of automation, accurate measurement and precise operation control. The molding equipment has the characteristics of reasonable structure design, convenient production operation, short molding cycle, high production efficiency and good product quality. The complete set of equipment includes: electronic metering device, loading system, mixing system, mixing system, pumping system, control system, cutting system and so on.

(A) Plant part

Production plant: height 5m, length 50 meters, width 20 meters or more, area 1000-1500m2

Finished product stacking area: area 1500m2------3000m2 (flexible adjustment according to sales volume)

Equipment dimensions: length 44 m X width 7.5 m X height 5 m

(B) Hydropower section

Total power of the plant: 100-200KW

Production water: 2400m3 / month or so (according to the size of production, based on actual production)

(C) Production of raw materials

1 cement: 425R Portland cement 2 fly ash raw ash (optional) 3 stone powder fine powder (optional) 4 sand (containing mud ≤ 2% (optional) 5 slag powder fine powder (optional) 6 additives (the company specializes for)

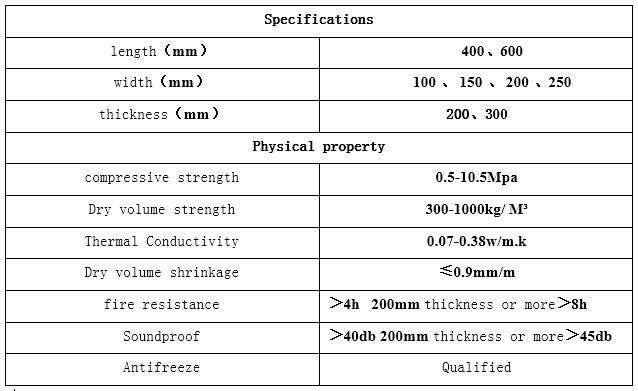

Third, the product's advantages and parameters

Lightweight, heat-insulating, heat-insulating, sound-proof, environmentally friendly, fire-resistant, drowning, easy to construct.

Application areas:

Industrial and civil buildings such as houses, hospitals, hotels, schools, shopping malls, supermarkets, factories, etc.

Application range:

The seismic fortification intensity is 8 (including 8) and below (if it is designed for 9 degrees);

Reinforced concrete structure with a height of less than 100m;

Steel structure non-load-bearing exterior wall, enclosure wall, roof and floor, height (single project of 100m or more and over-limit high-rise exterior wall panel design);

Interior walls (interior walls are generally not subject to height restrictions);

Various insulation and energy-saving buildings;

Factory, warehouse and other firewalls.