Customer Service Hotline:

400-831-9091

E-mail:gzhengde@163.com Tel:13924139149

ADD:Foshan rich Ann industrial zone rich even road no. 25

↵

TEL:400-831-9091

Copyright ©2018 Guangzhou Hengde Construction Technology Co., Ltd. All right reserved ICP:18070461-1

GUANGZHOU HENGDE

PRODUCT CENTER

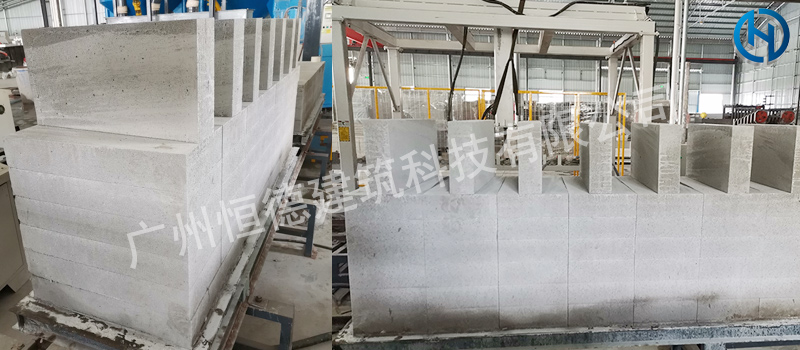

This large-scale integrated building materials machinery - non-autoclaved aerated block equipment (non-autoclaved but need to be maintained), using German advanced steam-free technology, investment costs only 20% to 10% of autoclaved block equipment, the construction cycle is short, The investment return is fast, the product fully meets the engineering application requirements, and the application range is wide.

First. Non-autoclaved Aerated block equipment

Because the company uses fully automatic equipment, Europe and the United States technology is advanced and practical. Small equipment uses only a small amount of mold, 4~6 workers can produce, the product can be demoulded quickly, and the equipment can be produced normally in spring, summer, autumn and winter. By replacing different molds, it is possible to produce a variety of products with good quality, in line with the development of green building industrialization, and provide a complete service system from plant planning, equipment installation to technical training.

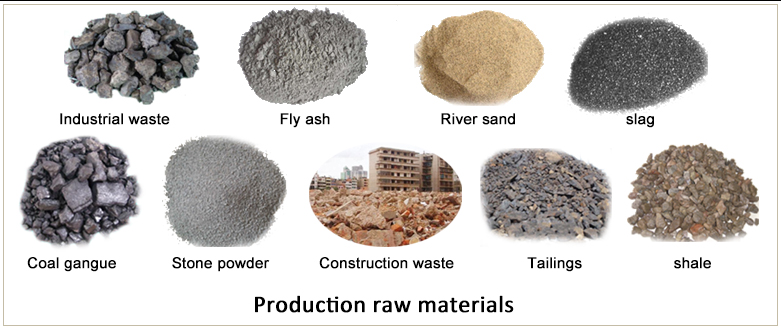

1. Raw materials: The non-autoclaved aerated block equipment uses industrial waste such as cement and fly ash, electric lime, sand and slag as raw materials (it can be produced in the same way), which is convenient in drawing and low in price, and has low production cost.

2. Investment advantage: The investment of this project is small, no autoclave is needed, only 20% to 10% of the investment in autoclaved gas filling equipment, and the operating cost is low. (calculated with an annual output of 50,000 cubic meters)

3. new technology and new technology: the introduction of European and American technology formula, the use of imported additives, high foaming rate, greatly reducing the water absorption rate of the aerated block products to improve the freeze-thaw resistance, so as to ensure high strength, no cracking and no water absorption. Exclusive 360-degree rotation and symmetrical cutting equipment ensure that the appearance of the product is neat and not broken.

4. Fully automatic advantage: The automatic control system is adopted to make the whole production line work more reliable. At the same time, the whole CNC technology can be used to accurately measure the feeding, high-speed stirring and rapid foaming, which simplifies the production process and saves manpower.

5. Advantages of cutting saw: high-strength block brick cutting, fast speed, neat appearance, standard size, no shortage of corners and other angles.

6. Environmental advantages: The whole production process does not discharge waste water and smoke, no pollution, low noise, no damage to cultivated land, and green production line.

7. Low cost: In the production, the mold cost, labor cost, damage rate cost, site cost and extended (winter) production time cost are reduced in large quantities, so the production cost is far lower than similar products, and the performance indicators are in line with the construction. Claim.

8. Equipment price: The degree of automation and configuration of the equipment is different, and the price is also different. We will adjust the configuration according to the different needs of customers, and the price of the equipment will be priced according to the configuration.

Second. Plant, water, electricity and production materials required for equipment

The production line adopts automatic batching and electronic metering, with high degree of automation, accurate measurement and precise operation control. The molding equipment has the characteristics of reasonable structure design, convenient production operation, short molding cycle, high production efficiency and good product quality. The complete set of equipment includes: electronic metering device, loading system, mixing system, mixing system, pumping system, control system, cutting system and so on.

(A) Plant part

Production plant: height 5m, length 50 meters, width 20 meters or more, area 1000-1500m2

Finished product stacking area: area 1500m2------3000m2 (flexible adjustment according to sales volume)

Equipment dimensions: length 45 meters * width 7.5 meters * height 5 meters

(B) Hydropower section

Total power of the plant: 100-200KW

Production water: 2400m3 / month or so (according to the size of production, based on actual production)

(C) Production of raw materials

1. Cement: 425R Portland cement 2, fly ash raw ash (optional) 3. Stone powder fine powder (optional) 4. Sand, (containing mud content ≤ 2% (optional) 5. Slag powder fine powder (optional) 6. Additives (specially provided by the company)

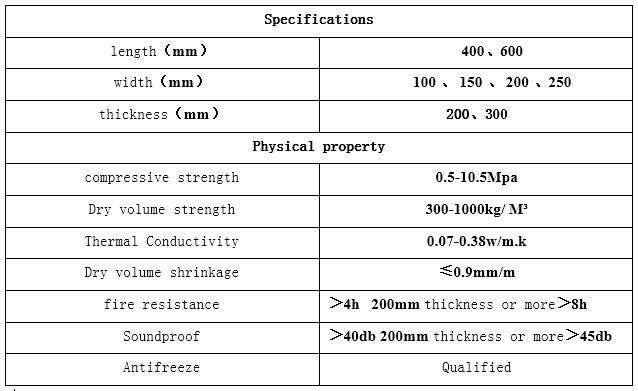

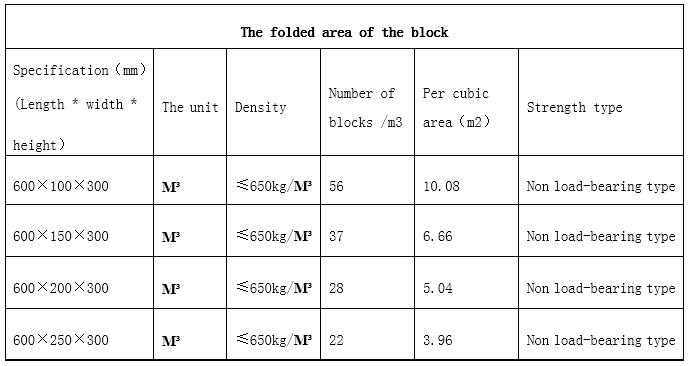

Third, the product's advantage parameters

Lightweight, heat-insulating, heat-insulating, sound-proof, environmentally friendly, fire-resistant, drowning, easy to construct

Application areas:

Industrial and civil buildings such as houses, hospitals, hotels, schools, shopping malls, supermarkets, factories, etc.

Application range:

The seismic fortification intensity is 8 (including 8) and below (if it is designed for 9 degrees);

Reinforced concrete structure with a height of less than 100m;

Steel structure non-load-bearing exterior wall, enclosure wall, roof and floor, height (single project of 100m or more and over-limit high-rise exterior wall panel design);

Interior walls (interior walls are generally not subject to height restrictions);

Various insulation and energy-saving buildings;

Factory, warehouse and other firewalls.