Customer Service Hotline:

400-831-9091

E-mail:gzhengde@163.com Tel:13924139149

ADD:Foshan rich Ann industrial zone rich even road no. 25

↵

TEL:400-831-9091

Copyright ©2018 Guangzhou Hengde Construction Technology Co., Ltd. All right reserved ICP:18070461-1

GUANGZHOU HENGDE

PRODUCT CENTER

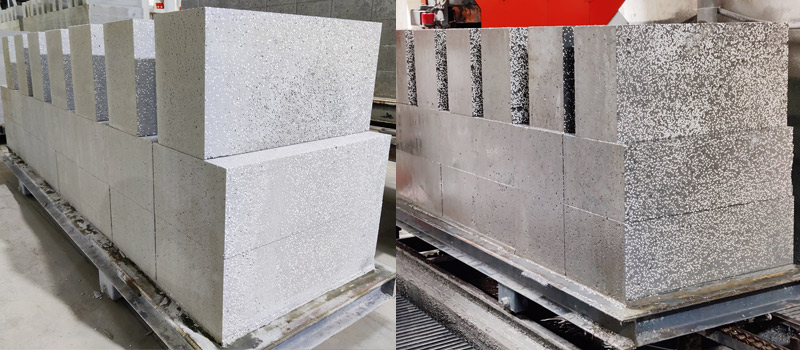

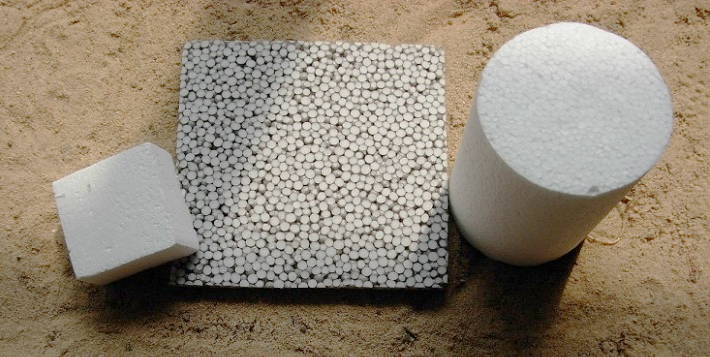

Polystyrene granule block is a new type of wall and thermal insulation material which is made by mixing and curing the foam concrete and polystyrene granule materials in a certain proportion according to the production process of “sanding sand”。 . Mainly used for exterior wall, it has the functions of light weight, heat preservation, heat insulation, moisture proof, sound absorption and sound insulation. It does not need additional insulation layer in the peripheral structure of the building. It can also be used as roof insulation material, which is a wall self-insulation material.

First. Introduction of polystyrene granule block production equipment

The polystyrene granule block equipment uses a cement foaming process to mix light concrete and polystyrene granules to produce a production line of energy-saving thermal insulation wall materials.

1. Automated operation. The production line uses an electronic control system with few people. Not only reduces production costs, but also greatly improves production stability.

2. High equipment output. The process of pouring, mixing, foaming and demoulding is fast and the daily output is high by the automatic feeding and batching system. Equipped with our proprietary high-precision cutting device, we can produce products with specified specifications.

3. The product quality is good. The products have passed the inspection quality certification of building materials, and the physical properties of the products exceed the standard requirements.

Second, polystyrene granule block product features

1, lightweight. Polystyrene pellets are made of polystyrene foamed pellets and foamed concrete. The bulk density is 500-800 kg/m3, which can reduce the main load and investment cost.

2, the effect of the advantage. The polystyrene granule block has less water absorption, which can reduce the series of defects such as hollowing and cracking of the inner and outer walls, and the product can be upgraded according to the design requirements (A2.5-A3.5)。

3. Low cost. Polystyrene pellets, because of their own heat transfer coefficient and thermal inertia indicators have reached energy-saving requirements (energy saving of more than 60%), the wall does not need to do external insulation treatment, thus reducing the construction cost.

4, insulation and energy saving. Polystyrene granule block contains the characteristics of polystyrene foamed granules and foamed concrete. Its heat preservation and wall are “two-in-one”。 It can avoid the common problem of detachment and cracking of outer wall outer layer without additional external insulation.

5. Construction efficiency. Polystyrene granule block is the most convenient construction specification. It is a product that is easy to understand and simple and quick to construct.

Third. Plants, hydropower and raw materials required for equipment

The production line adopts automatic batching and electronic metering, with high degree of automation, accurate measurement and precise operation control. The molding equipment has the characteristics of reasonable structure design, convenient production operation, short molding cycle, high production efficiency and good product quality. The complete set of equipment includes: electronic metering device, loading system, mixing system, mixing system, pumping system, control system, cutting system and so on.

(A) Plant part

Production plant: height 5m, length 50 meters, width 20 meters or more, area 1000-1500m2

Finished product stacking area: area 1500m2------3000m2 (flexible adjustment according to sales volume)

Equipment dimensions: length 45 meters * width 7.5 meters * height 5 meters

(B) Hydropower section

Total power of the plant: 100-200KW

Production water: 2400m3 / month or so (according to the size of production, based on actual production)

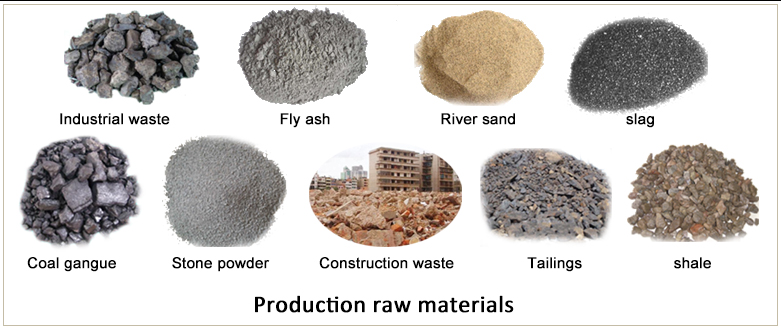

(C) Production of raw materials

1. Cement: 425R Portland cement 2, polyphenyl granules 3, fly ash raw ash (optional) 4, sand, (containing mud ≤ 2% (optional) 5, stone powder and slag fine powder (optional) 6, Additives (specially supplied by the company)